3D printing has revolutionized the way we create and manufacture objects, and Singapore is no exception. Singapore’s 3D printing industry has grown significantly in recent years, with a range of companies offering 3D printing services, materials, and accessories. From prototyping to production, individuals and businesses can take advantage of the technology’s benefits.

Understanding 3D printing is crucial to appreciate how it works. 3D printing is a process of creating three-dimensional objects from a digital file. The printer creates the object by adding material layer by layer until the final product is complete. The materials used in 3D printing can vary, including plastics, metals, and even food. The possibilities are endless, and the technology is continually advancing.

There are several 3D printing companies in Singapore, offering a range of services such as prototyping, production, and design. Additionally, there are several suppliers of 3D printers and accessories.

The technology is being used in various industries, including healthcare, education, and manufacturing, to name a few. The future of 3D printing is exciting, with the potential to transform traditional manufacturing processes.

Key Takeaways

- Singapore’s 3D printing industry has grown significantly in recent years, with a range of companies offering 3D printing services, materials, and accessories.

- 3D printing is a process of creating three-dimensional objects from a digital file, and the materials used can vary, including plastics, metals, and even food.

- The technology is being used in various industries, including healthcare, education, and manufacturing, and has the potential to transform traditional manufacturing processes.

Understanding 3D Printing

Fundamentals of 3D Printing

3D printing is a technology that allows users to create three-dimensional objects from digital models. The process involves adding material layer by layer until the desired object is formed. This technology has revolutionized various industries, from manufacturing to healthcare, and is increasingly being used in Singapore.

The most common 3D printing technology is Fused Deposition Modelling (FDM), which involves melting a plastic filament and depositing it layer by layer to create the object. Stereolithography (SLA) is another popular technology that uses a liquid resin and a laser to create the object. Digital Light Processing (DLP) is similar to SLA but uses a projector instead of a laser.

3D Printing Technology

3D printing technology has come a long way since its inception. Today, 3D printers can create objects using a variety of materials, including plastics, metals, and even living cells. This technology has the potential to revolutionize manufacturing, as it allows for the creation of complex objects without the need for expensive tooling.

Fused Deposition Modelling (FDM) is the most popular 3D printing technology due to its affordability and ease of use. It is also the most widely available technology, with many manufacturers producing FDM printers for home and industrial use. Stereolithography (SLA) and Digital Light Processing (DLP) are more expensive and less widely available, but offer higher resolution and greater accuracy.

3D Printing Methods

There are several 3D printing methods available, each with its own advantages and disadvantages. Fused Deposition Modelling (FDM) is the most common method and is ideal for creating large, durable objects. Stereolithography (SLA) and Digital Light Processing (DLP) are ideal for creating small, intricate objects with high levels of detail.

Other 3D printing methods include Selective Laser Sintering (SLS), which uses a laser to sinter powdered material together, and Binder Jetting, which uses a liquid binder to bond powdered material together. These methods are less common but offer unique advantages in certain applications.

Overall, 3D printing technology is rapidly advancing and has the potential to revolutionize various industries. From creating prototypes to producing final products, 3D printing offers a cost-effective and efficient way to manufacture objects. With the increasing availability of 3D printers in Singapore, it is an exciting time for the industry and its applications.

Materials Used in 3D Printing

3D printing has revolutionized the manufacturing industry by allowing for the creation of complex and intricate designs that were previously impossible to produce. The process involves the layer-by-layer addition of material to create a three-dimensional object. The materials used in 3D printing are crucial to the quality and durability of the final product.

Common 3D Printing Materials

The most common materials used in 3D printing are PLA, PP, and ABS. PLA (polylactic acid) is a biodegradable thermoplastic made from natural sources such as corn or sugarcane. It is easy to use and produces high-quality prints with a glossy finish.

PP (polypropylene) is a thermoplastic polymer that is lightweight, durable, and has excellent chemical resistance. It is commonly used in the food packaging industry. ABS (acrylonitrile butadiene styrene) is a strong and durable thermoplastic that is commonly used in the automotive and consumer goods industries. It can withstand high temperatures and is resistant to impact and abrasion.

Industrial 3D Printing Materials

Industrial 3D printing requires materials with higher strength and durability than those used in common 3D printing. Some of the most commonly used industrial 3D printing materials include nylon, carbon fiber, and metal. Nylon is a strong and flexible material that is commonly used in the aerospace and automotive industries.

Carbon fiber is a lightweight and strong material that is commonly used in the manufacturing of high-performance parts. Metal 3D printing involves the use of metal powders such as titanium, aluminum, and stainless steel to create parts with high strength and durability.

In addition to these materials, there are also specialized filaments and materials that are designed for specific applications. For example, there are filaments that are infused with wood, metal, or carbon fiber to create unique textures and finishes. There are also filaments that are designed for specific applications such as medical implants, food packaging, and electrical components.

In conclusion, the materials used in 3D printing are diverse and constantly evolving. The choice of material depends on the application and desired properties of the final product. As the technology continues to evolve, we can expect to see new and innovative materials being developed for use in 3D printing.

3D Printing Services in Singapore

Singapore is a hub for 3D printing services, with a variety of companies offering commercial and industrial 3D printing services, as well as 3D printing services for education.

Commercial 3D Printing Services

For businesses looking to create prototypes or small production runs, there are several 3D printing services in Singapore that offer commercial-grade printing. Companies like 3D Print Singapore and Additive3D Asia specialize in manufacturing, prototyping, and low-volume production. They offer a range of materials, finishes, and printing technologies to meet the specific needs of their clients.

Industrial 3D Printing Services

Singapore is also home to several companies that offer industrial-grade 3D printing services. ZELTA 3D is a leading provider of industrial 3D printing services in Singapore, offering high-quality parts in multi-materials with automotive-grade finishes. They utilize advanced 3D printing technologies and proprietary software and hardware automation to produce parts quickly and efficiently.

3D Printing for Education

Singapore is committed to promoting STEM education, and 3D printing is an important part of that effort. Companies like 3D Generation offer 3D printing services for educational institutions, helping students and teachers bring their ideas to life. They offer a range of services, including 3D modeling, scanning, and printing, as well as post-production services like CNC and injection molding.

Overall, Singapore offers a diverse range of 3D printing services, from commercial and industrial-grade printing to educational services. These companies utilize advanced technologies and materials to produce high-quality parts and prototypes quickly and efficiently.

3D Printers and Accessories

3D printing technology has revolutionized the way we manufacture products, allowing us to produce complex designs and prototypes quickly and efficiently. In Singapore, there are many options when it comes to choosing a 3D printer and its accessories.

Choosing a 3D Printer

When selecting a 3D printer, there are several factors to consider. The most important ones are the printer’s build volume, accuracy, and speed. A printer’s build volume refers to the maximum size of the object it can print. Accuracy is the level of detail a printer can produce, while speed is the time it takes to complete a print job.

Other factors to consider include the type of filament used, the printer’s connectivity options, and the software used to control the printer. Some popular 3D printers available in Singapore include the Ultimaker S5, the MakerBot Replicator+, and the Prusa i3 MK3S.

Understanding 3D Printer Accessories

In addition to 3D printers, there are many accessories available that can enhance the printing experience. These include:

- Filament: The material used to create the object being printed. Filament comes in a variety of materials, including ABS, PLA, and PETG.

- Print bed: The surface on which the object is printed. A heated print bed can improve adhesion and reduce warping.

- Nozzle: The part of the printer that melts the filament and deposits it onto the print bed. Different nozzle sizes can affect print quality and speed.

- Extruder: The part of the printer that feeds the filament into the nozzle. A high-quality extruder can improve print quality and reduce the risk of jams.

- Cooling fan: Helps to cool the printed object, preventing warping and improving the overall finish.

- Enclosure: A cover that surrounds the printer, helping to maintain a consistent temperature and reducing noise.

When choosing accessories, it’s important to ensure that they are compatible with your printer. Some popular accessory brands available in Singapore include Ultimaker, MakerBot, and Prusa.

In conclusion, 3D printing in Singapore offers a wide range of options when it comes to printers and accessories. By considering factors such as build volume, accuracy, and speed, as well as choosing the right accessories, individuals and businesses can take full advantage of this exciting technology.

3D Printing Companies in Singapore

Singapore is home to some of the best 3D printing companies in the world. These companies offer a wide range of 3D printing services, from prototyping to production, and use the latest technologies to deliver high-quality parts in a timely manner.

Additive3D Asia

Additive3D Asia is a renowned leader in digital manufacturing based in Singapore. The company offers a wide range of 3D printing services, including prototyping, production, and post-processing.

Additive3D Asia uses the latest technologies to produce high-quality parts in multi-materials, automotive grade finishes in as fast as 1 business day. The company also offers design consultation and 3D scanning services to help clients bring their ideas to life.

Next Manufacturing

Next Manufacturing is a 3D printing company based in Singapore that offers a wide range of 3D printing services, including prototyping, production, and post-processing.

The company uses the latest technologies to produce high-quality parts in a timely manner. Next Manufacturing also offers design consultation and 3D scanning services to help clients bring their ideas to life. The company prides itself on its commitment to quality, reliability, and customer satisfaction.

In addition to these companies, there are many other 3D printing companies in Singapore that offer a wide range of services. These companies include Zelta 3D, 3DPS LLP, and 3D Aura, among others. With so many options available, it’s easy to find a 3D printing company in Singapore that can meet your needs.

3D Printing for Different Industries

3D printing has revolutionized the manufacturing industry by providing a faster, more efficient, and cost-effective alternative to traditional manufacturing methods. This technology has been adopted by various industries, including architecture, medical, automotive, and semiconductor.

3D Printing in Architecture

Architects use 3D printing to create scale models of buildings and other structures. This technology allows architects to create intricate designs and test them before construction begins. 3D printing also enables architects to create models of complex shapes that would be difficult to produce using traditional manufacturing methods.

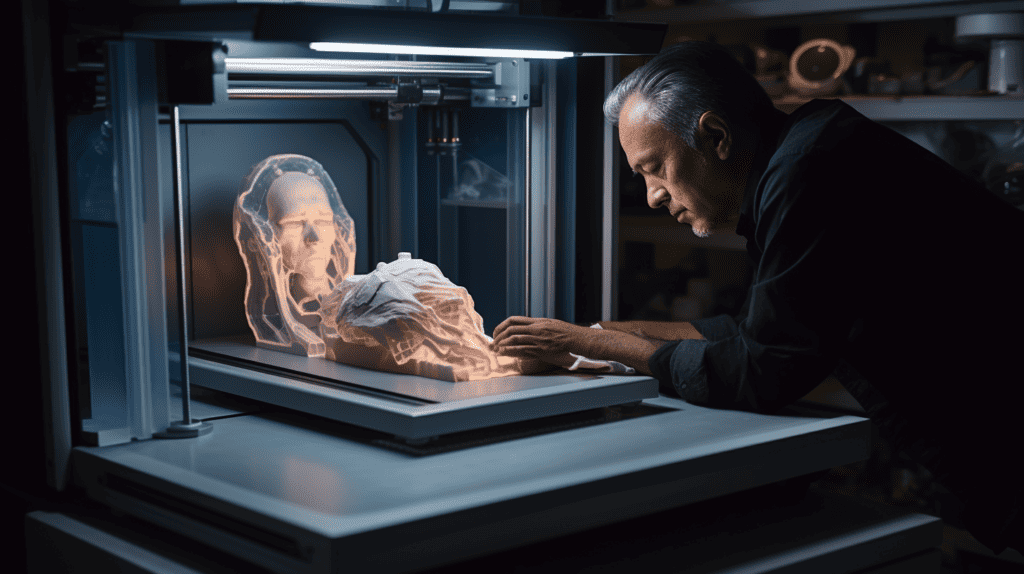

3D Printing in Medical Field

3D printing has been used in the medical field to create prosthetics, implants, and surgical models. This technology enables medical professionals to create custom-made prosthetics and implants that fit the patient’s body perfectly. 3D printing has also been used to create surgical models that allow doctors to practice surgeries before performing them on the patient.

3D Printing in Automotive Industry

The automotive industry has adopted 3D printing to create prototypes, parts, and tools. This technology enables designers to create and test prototypes quickly and efficiently. 3D printing also allows manufacturers to produce parts that are difficult or impossible to produce using traditional manufacturing methods.

3D Printing in Semiconductor Industry

The semiconductor industry has adopted 3D printing to create prototypes and parts for electronic devices. This technology enables manufacturers to create complex parts with high precision and accuracy. 3D printing also allows manufacturers to produce parts with unique shapes and designs that would be difficult to produce using traditional manufacturing methods.

In conclusion, 3D printing has revolutionized the manufacturing industry by providing a faster, more efficient, and cost-effective alternative to traditional manufacturing methods. This technology has been adopted by various industries, including architecture, medical, automotive, and semiconductor.

The Future of 3D Printing

Exciting advancements are on the horizon for 3D printing in Singapore. As the world continues to move towards digital manufacturing, the potential for 3D printing to revolutionize the industry is becoming increasingly apparent.

One area where 3D printing is expected to have a significant impact is in the medical field. With the ability to create custom prosthetics and implants, 3D printing has the potential to transform the way doctors approach patient care.

In Singapore, the National University Hospital has already started using 3D printing to create models of patients’ organs, allowing doctors to better plan surgeries and improve patient outcomes.

Another area where 3D printing is expected to make waves is in the construction industry. By using 3D printing to create building components, construction companies can reduce waste and improve efficiency. Singapore is already home to several companies that are exploring the use of 3D printing in construction, including Concreative and HDB.

As 3D printing technology continues to improve, the possibilities for its use will only continue to expand. In the future, it may be possible to 3D print entire buildings or even human organs. With Singapore’s focus on innovation and technology, it is likely that the country will continue to be at the forefront of 3D printing research and development.

Overall, the future of 3D printing in Singapore is bright. As the technology continues to evolve, it has the potential to transform multiple industries and improve the lives of people around the world.

Frequently Asked Questions

What are the top FDM printer brands in Singapore?

There are several top FDM printer brands in Singapore, including Ultimaker, MakerBot, and Prusa. These brands are known for their high-quality printers that can produce accurate and detailed prints.

Who are the best medical 3D printing companies in Singapore?

Some of the best medical 3D printing companies in Singapore include Creatz3D and Siege Advanced Manufacturing. These companies have experience in producing high-quality medical models and equipment using 3D printing technology.

Where can I find affordable 3D printing services in Singapore?

There are several places where you can find affordable 3D printing services in Singapore, such as 3D Print Singapore and Additive3D Asia. These companies offer a range of services at competitive prices.

What are the advantages of metal 3D printing in Singapore?

Metal 3D printing offers several advantages in Singapore, such as the ability to produce complex and intricate designs, reduce material waste, and improve production efficiency. Some of the top metal 3D printing companies in Singapore include Creatz3D and Siege Advanced Manufacturing.

How does resin 3D printing compare to other methods in Singapore?

Resin 3D printing offers several advantages over other methods in Singapore, such as the ability to produce highly detailed and accurate prints with smooth surfaces. However, it can be more expensive than other methods and requires more post-processing work. Some of the top resin 3D printing companies in Singapore include Siege Advanced Manufacturing and Additive3D Asia.

What is the 3D printing industry like in Singapore?

The 3D printing industry in Singapore is growing rapidly, with several companies offering a range of services and products. The industry is expected to continue to grow in the coming years, as more businesses and industries adopt 3D printing technology for their production needs.